1. Effects of Passivation Layer on Material Properties

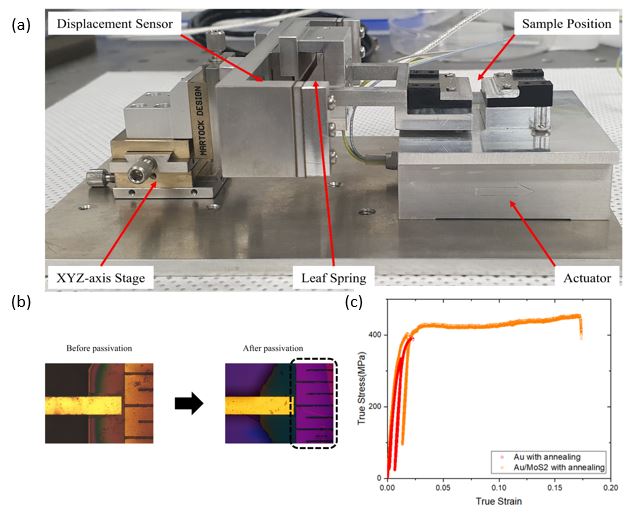

The mechanical behavior of metallic thin films can be changed when they are layered with other thin materials due to the existence of interface. Therefore, understanding the performance of metallic thin films with and without a passivation layer is important. To compare the mechanical behavior of freestanding and passivated thin films, we utilized a custom-built tensile tester which has a stroke of 250μm with a displacement resolution of 10nm and a load resolution 9.7μN. Freestanding specimens were fabricated with MEMS process, and 2D MoS2 passivation layers were transferred on water. Stress-strain curves showed a significant increase in elongation for metallic films with passivation layer, which is attributed to the delay in the strain localization due to constraint imposed by ultra-thin passivation layer.

The mechanical behavior of metallic thin films can be changed when they are layered with other thin materials due to the existence of interface. Therefore, understanding the performance of metallic thin films with and without a passivation layer is important. To compare the mechanical behavior of freestanding and passivated thin films, we utilized a custom-built tensile tester which has a stroke of 250μm with a displacement resolution of 10nm and a load resolution 9.7μN. Freestanding specimens were fabricated with MEMS process, and 2D MoS2 passivation layers were transferred on water. Stress-strain curves showed a significant increase in elongation for metallic films with passivation layer, which is attributed to the delay in the strain localization due to constraint imposed by ultra-thin passivation layer.

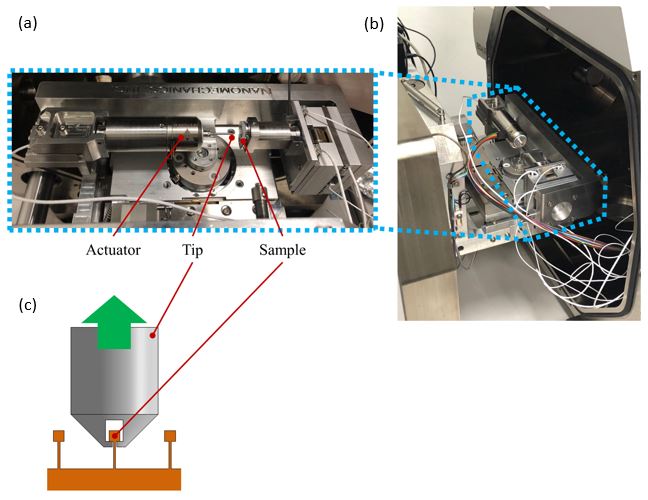

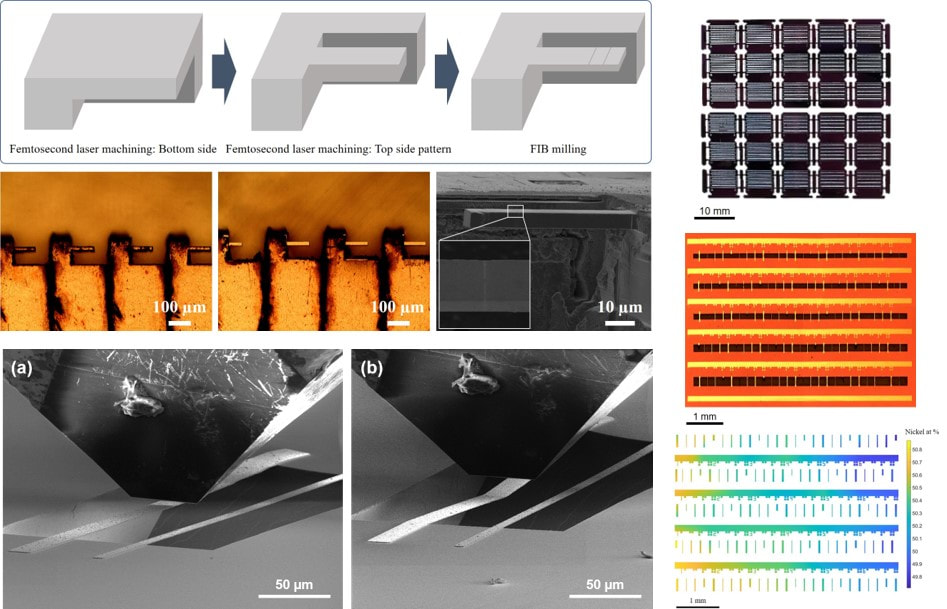

(a) Custom built in-situ SEM tensile tester, (b) optical microscope images of freestanding Au thin films with and without passivation layer, and (c) true stress-strain curve of Au thin films with and without passivation layer.